In-liquid plasma Application Technology

The in-liquid plasma technology research is one of the research projects in Ehime university that has been established in 2002 assisted by the faculty of engineering, science, agriculture, and the integrated center of sciences in Ehime university.

In this project, the basic and advanced researches related to in-liquid plasma process, sono-process, laser measurement, plasma for medical application, have been investigated by the cooperation researches based on plasma physics and engineering, chemical engineering, thermal and fluid engineering, electromagnetic wave and high frequency wave Engineering, acoustic engineering, etc.

Chemical Vapor Deposition

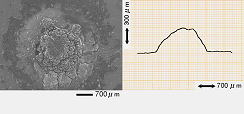

Diamond-Like Carbon (DLC)

Since it is possible to achieve extremely hard and smooth surfaces through the application of coatings to materials, it is also possible to reduce the frictional force that results from contact between materials. The coatings, therefore, are usable in the abrasion, wear and corrosion resistance of machine parts.

Left:SEM photo of a DLC film,Right:cross-section

(n-dodecane,100hPa,Plasma generation time 3 mins)

Polycrystalline Silicon Carbide

Compared to silicon, the material which is currently employed in the fabrication of the majority of semi-conductors, silicon carbide, is capable of maintaining stable properties in far more severe environments. As a result of this, there are great expectations for it as the essential component of the next generation of semi-conductors.

SEM photo of an SiCfilm

(Silicon Oil,25hPa,Plasma generationtime 1mins)

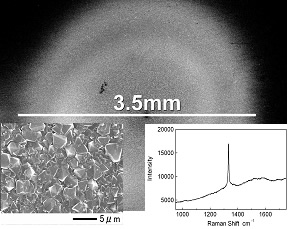

Diamond

Diamond has a number of desirable properties such as highest hardness and thermal conductivity, high electrical resistivity. We proposed the possible use of an in-liquid plasma process for diamond film deposition instead of conventional gas phase plasma CVD.

(Methanol, deposition area : 3.5mm dia., 600hPa、3min)

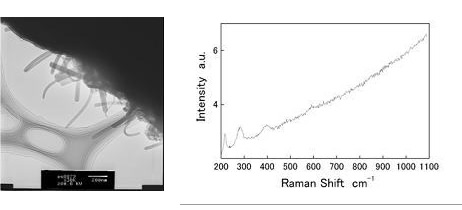

Catalysis Chemical Vapor Deposition in Liquid

There is much expectation about the use of this nano-technology in a wide range of fields, such as electronics. There is also great expectation for it in the large-scale composition of fullerene or nanotube.

SEM photo of carbon nanotube, Nano-tube Raman spedtrum

(benzenliquid containing ferrocene +Fe support zeolite, atomospheric pressure)

Decomposition of Harmful Substance and The Production of Fuel Gas

Freon, dioxin and PCB are harmful substances that have caused environmental concerns. It may now be possible to more efficiently breakdown these substances and render them harmless.

Not only is highly efficient fuel generation made possible, but it is also possible to attain it as a by-product of the carbon materials production process.

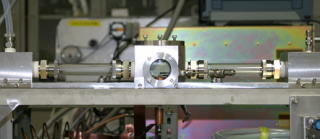

Reator capable of continuous processing of in-liquid plasma

Supercritical fluid plasma

Supercritical fluids have high density and the solvent power as liquids along with high transfer speed and high osmotic force. We investigate the generation of high-frequency plasma in supercritical fluid and propose new plasma proceeding.

|

|

| Plasma generation in supercritical carbon dioxide(20MPa) |

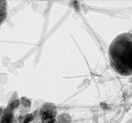

Tungsten oxide nanowires coated with amorphous carbon |

Devices and Instruments

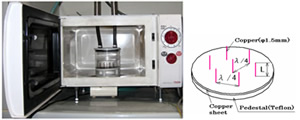

he energy source used was microwaves, high frequency wave(HF) or Radio frequency wave(RF). No particularly large devices were required in the plasma generation, and the plasma was generated at room temperature and normal atmospheric pressure.

|

|

| In-liquid plasma CVD device | High pressure in-liquid plasma device |

|

|

| Reactor capable of continuous processing | Plasma device by using a conventional microwave oven Japanese patent No.3769625 Korean patent No.0934139 |